I am taking the winter jacket course again with Mme Dorothee Barnes at

Club Tissus in Laval. Simon and I originally took the course together in 2013. We both made our own winter jackets, and we still wear them to this day (Ok, not today as it is UNUSUALLY HOT this late October, but you understand what I mean!) You can see

My Jacket and

Simon's Jacket here.

We were so happy with the process that we bought all the materials to make me a long red jacket. We planned on making a version of Kanuk's Blainville jacket, but longer. Guess what happened? Yup, you guessed it. It went in the stash pile. I stored everything in a Rubbermaid bin.

So enter 2017, 4 years later. I signed Simon and I up for the course. We ended up with only me taking the course. With Simon starting a new job that finished much later and a strain on babysitting, it is only me.

It is much easier on the time budget working only on one coat at a time!

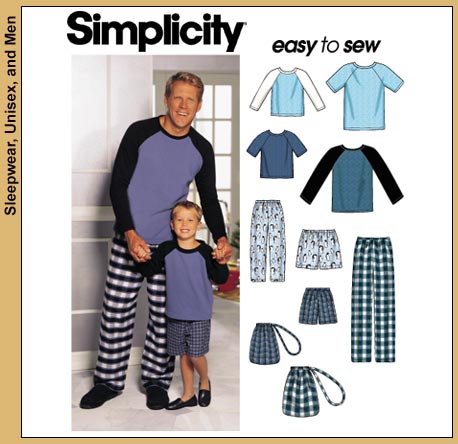

We used Jalie 2108 as the base model for the jacket. We added princess seams, changed the collar, the width, the length, just about everything! I wanted a nice long jacket for when I wear skirts to work. Something sleek with not much details. I added a band in the front middle for details.

I am now stuck on the hood. We have decided to purchase removable fur like in the picture above. We are not sure if we want to add a drawstring to the hood, and we are waiting on the color of the fur to decide the color of our polar blizzard fleece for the collar. Other than that after this week's class I will be done!

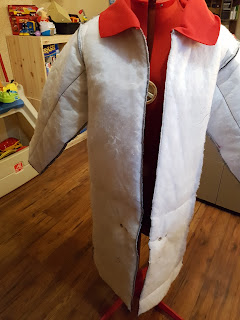

Here is the exterior shell. I created the princess seams and sewed the pockets in the seams. I added a horizontal band for detail.

You can see the exterior portion of collar was made with exterior nylon and 200g earthwrap.

As you can see the pockets do not lay flat. What we ended up doing was to see a piece of fabric from the pocket to the edge. That way the pocket stays in place. A small detail but trust me in the end it makes a big difference!

Here is the back of the jacket: the collar and zipper shield

The shield is 5cm longer than the zipper.

The interior lining with the 200g Earthwrap insulation does not look like much. I attached the polar fleece for the collar to the lining.

The inside is much nicer to look at. I added a jupette, not a drawstring.

I HATE attaching the jupette and then the zipper. So we added snaps directly on the facing.

Another detail is to add a hook to hang up your jacket.

Here is where I am with the hood. I attached the zipper but I did not sew the interior tot he exterior shell.

I am not adding a drawstring or side shields on this hood.

I am adding removable fur to the hood collar. I need the sew a shield with snaps to add to the fur, and snaps to the hood portion as well. To do this I need to go to the fabric store and use their snap press. So I have to wait to sew up the hood to do this.

This is the first time we use the magnetic snaps. A word of caution: Make sure your flap is wide enough, or else you will be cursing when you sew your lining to the exterior.

I added the duct tape to the shoulder seams. This will make it even more waterproof during those nasty storms. And no, it will not come off. We don't have regular duct tape, but we have the tape used on the exterior of the house, so you KNOW it will stick!

Here you can see the flap that Simon sewed on the pockets to keep them in place.

That added detail makes the lines of the jacket more professional and less homemade.

It was very difficult to sew the arms. I can't explain how we sewed the the lining and the exterior together, Our first attempt we ended up with the two sewed up so that we could not put on the jacket. OOPS.

I brought up a YouTube video and then it made sense. You have to go from the bottom, pull it out and place the right sides together.

I am a visual person, so don't ask me what we did, but it worked!

It is a good thing that we have the Janome MC 8200. There is a lot if room to the right of the presser foot. Otherwise it would have been pretty cramped!

Now all we have left is the bottom, turn it out, sew up the side arm seam, topstitch and finish the hood (snaps for fur, etc)

A trick Simon used when sewing the cuffs was he pre-twisted the jacket so that as he sewed the jacket unwound instead of twisting. It made it move easier under the machine.

So off to Club Tissue to use their snap machines. Now I say bite the bullet, buy 2 snap machines, be done with it and install them in your house. One for the top, one for the bottom rivets. No need to change the bits. Why spend the money you ask? Have

you ever been to a fabric store and

not spent money? What we spent today on material for yet more projects I could have easily bought 2 machines and bits.

Ok snow I am ready!